Additional information

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| In Stock / Available to Order |

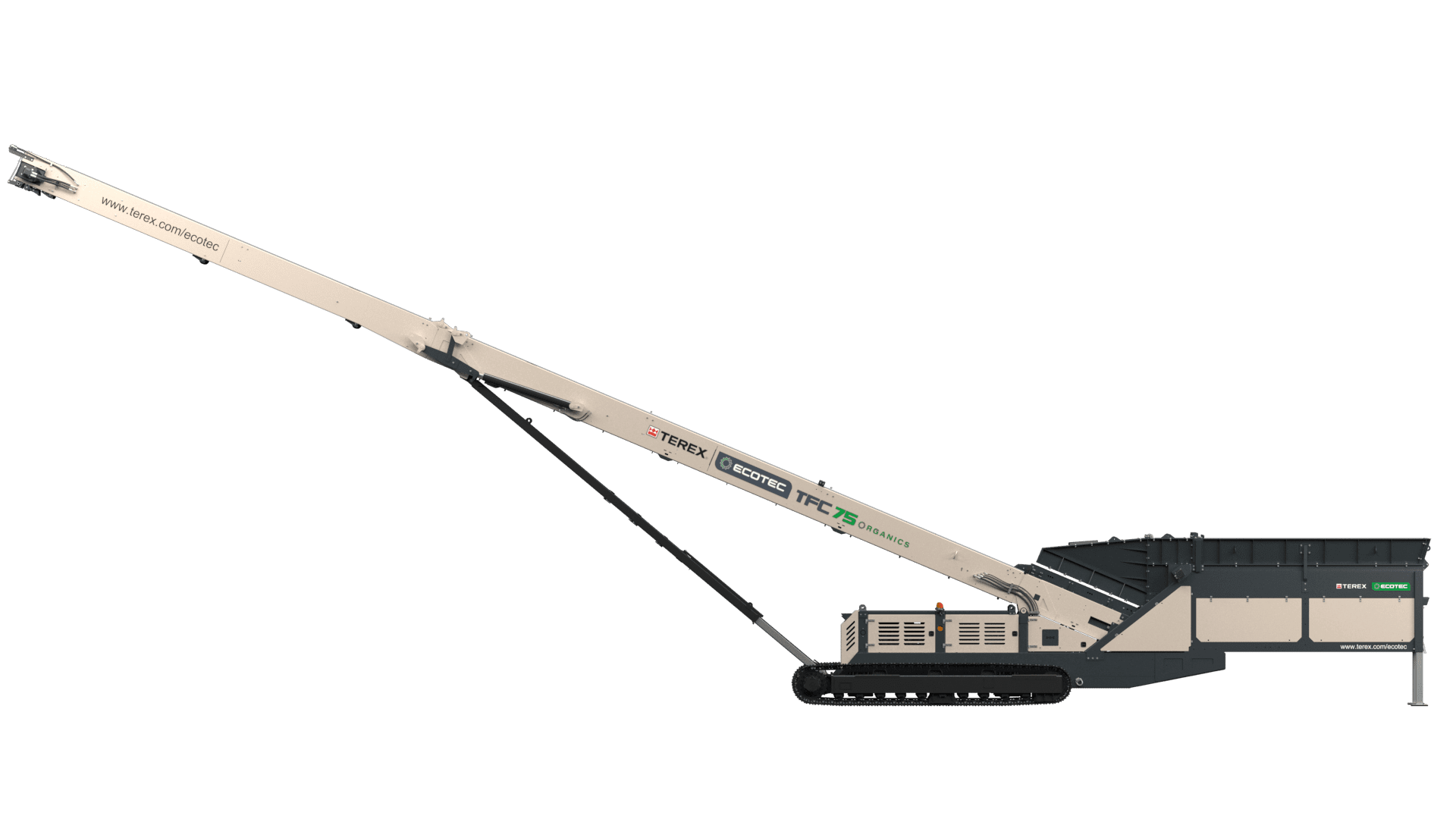

The TFC 75 Organics high-level feeder has been engineered specifically for the stockpiling and aerating of lower density, bulky materials such as soil, mulch, biomass, and compost. Located at the hopper outlet, the auger provides aeration and an untangling solution for organic materials. The auger flips, rotates, and regulates the flow of material minimizing fluctuations in the bulk density of organic materials, and is equipped with replaceable hardened paddle wear plates. High capacity, bespoke hopper design efficiently transfers and prevents the bridging of material. The reverse functionality of the feeder enables blockages to be cleared and oversized material removed. Controlled and efficient flow of material is guaranteed due to the adjustable operating speed of the feeder belt.

Get More InfoApplication: Soil, Mulch and Compost, Wood Recycling and Forestry

Manufacturer: Ecotec

Configuration: Mobile (Tracked)

Performance Highlights

Options

Designed specifically for the stockpiling and aerating of lower density, bulky materials such as soil, mulch, biomass, and compost, the TFC 75 organics high-level Feeder features an auger that flips and rotates the material untangling and separating it.

The high capacity, bespoke hopper is specifically designed to prevent bridging of low dense, bulky materials.

Fully protected Caterpillar C4.4 4-cylinder power-unit provides easy ground access for service and maintenance.

The TFC 75 high-level feeder stacking conveyor comes with an extensive list of custom options for application versatility including overband magnets, dust covers, radio remotes, 3-ply belts, dust suppression and much more.

Ecotec’s broad range of equipment allows for more targeted efficiency in niche operations. Behind an aggressive research and development strategy, Terex Ecotec now offers a full product portfolio that meets the needs of today’s professionals and will shape the industry for years to come. The Terex Ecotec product line has grown significantly and expanded production out of a new 105,000 square foot manufacturing facility Today their comprehensive product portfolio includes, Slow, Medium & High Speed Shredders, Trommel Screens, Recycling Screens, Waste Handlers, and conveyors.

Ecotec is your proven industry-leading partner for the design, service, and support of primary waste recycling, wood recycling, and composting equipment. They have dedicated sales and service staff for the Ecotec product range with a driving focus on providing customers the best support in and out of the field. Their world-class dealer distribution network provides the sales and aftermarket service demanded in the marketplace giving customers the support required to maximize production and minimize downtime.

Terex® Ecotec, part of the wider Terex Materials Processing group, is an industry leader in the design and manufacture of wood processing, biomass, and recycling equipment. The range of innovative machines available is robust yet user-friendly with a focus on throughput, efficiency, and serviceability. Their world-class range of mobile equipment that will shape the industry for years to come.

| Application | |

|---|---|

| Configuration | |

| Manufacturer | |

| Model | |

| In Stock / Available to Order |